Tomas Chvostek

Executive Director

E-mail:

tomas.chvostek@dryicetechnology.cz

Phone:

+420 608 977 417

Tomas Chvostek

Executive Director

E-mail:

tomas.chvostek@dryicetechnology.cz

Phone:

+420 608 977 417

AREAS OF APPLICATION

Dry ice can be used almost anywhere due to its properties. It is a gentle cleaning method that is highly effective but does not damage the surface being cleaned.

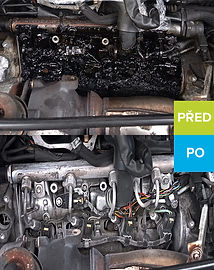

Automotive industry

Automotive workshops often struggle with grease and deposits that slow down work. With dry ice, you can remove dirt quickly and without dismantling components. For example, you can restore the functionality of a paint line during an hour-long shutdown instead of a day's downtime.

Energy and utilities

Cleaning electrical components is always risky, but it extends their lifespan. Dry ice differs from other methods by providing a non-conductive and safe alternative that eliminates the risk of short circuits and minimizes downtime. It can be used in applications such as: cleaning generators, turbines, electrical distribution and infrastructure.

Historic preservation and art

Preserving history requires gentle procedures. Dry ice allows you to remove graffiti, paint or organic deposits without damaging valuable and fragile materials. The perfect solution for valuable pieces of history.

Wooden buildings and furniture

Wood restoration can be difficult, but dry ice ensures that even old furniture or wooden buildings regain their beauty without damaging the surface. The process of restoring a 100-year-old cottage took a fraction of the time compared to traditional methods thanks to dry ice, and the surface was completely undamaged as a result. Typical applications: cleaning wood, wooden buildings, old furniture and wooden sculptures.

Communes and villages

Graffiti and chewing gum are a problem in many cities and towns. This method can be used to thoroughly clean walls and surfaces.

Food and pharmaceutical industry

Unlike chemical cleaning, dry ice is safe for use in hygiene-sensitive environments because it leaves no chemicals or moisture, eliminating bacteria without leaving any mess or contamination. Effective in applications such as: cleaning production lines, food molds, packaging equipment, and refrigeration systems.

Plastics and molding

Gentle cleaning without damaging surfaces ensures longer mold life and production process stability. It can be used, for example, to remove plastic residue and dust from molds, tools and production equipment.

Ventilation

Dry ice is the ideal solution for cleaning air conditioning and ventilation systems. It quickly and effectively removes dust, grease and other contaminants from hard-to-reach places without damaging sensitive components or leaving behind moisture. Thanks to this technology, it is possible to improve air quality and extend the life of the equipment.

Other uses of dry ice

Cooling and transportation

Unlike conventional refrigeration, dry ice provides a constant temperature and gradually sublimes, which minimizes the risk of contamination and makes it easier to handle during long-distance transport. Applications in the transport of food, pharmaceutical products, biological samples and chemicals that require a stable low temperature.

Dust removal and decontamination

Dry ice safely removes dust and contaminants from hard-to-reach areas without the use of chemicals or water. It is commonly used in cleaning and decontamination of sensitive equipment, laboratory equipment, or complex surfaces.

Surface preparation before painting or finishing

Surfaces require thorough cleaning before painting or refinishing. Dry ice removes grease and old paint quickly and without residue, ensuring perfect preparation for finishing. It is commonly used to remove old paint, grease and other contaminants before refinishing or painting.